carpy impact testing|charpy impact testing methods : Chinese The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure the . Copa Libertadores. Confira a programação de jogos. Classifi.

{plog:ftitle_list}

WEBOs verbos referentes às vozes dos animais são geralmente considerados unipessoais pelas gramáticas tradicionais, isto é, são apresentados como tendo flexões apenas na .

This makes Charpy testing a popular choice for assessing the toughness of metals like steel, as well as polymers, composites, and ceramics. Here’s how the process works: The test .The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This .The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure the .Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .

The Charpy impact test, introduced by Georges Augustin Albert Charpy (1865–1945) in 1901, is widely utilized for efficiently evaluating the toughness of materials. This method assesses the energy absorbed by a .The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction .シャルピー衝撃試験機. シャルピー衝撃試験(シャルピーしょうげきしけん、英: Charpy impact test )とは、切り欠きのはいった角柱状の試験片に対して高速で衝撃を与えることで試験片を破壊し、破壊するために要したエネルギーと試験片の靭性を評価するための衝撃試験である。

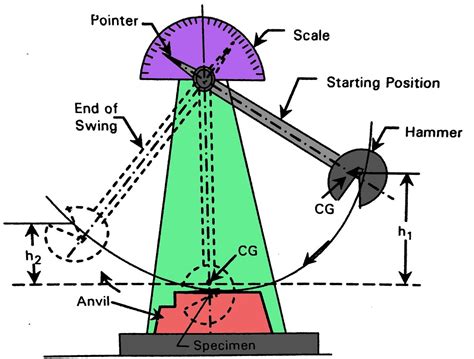

Charpy impact test results are measured in joules, the SI unit for energy. This is simply the amount of work performed by a 1-newton force pushing a sample by 1 m in the direction of the force. This value can be used to . History of the Charpy impact test. The history of Charpy V-notch impact testing dates back to the early 1900s when French engineer Georges Charpy developed a standardized method for testing the impact toughness .One of the most common tests performed with pendulum impact testers is the Charpy test, which has also earned these machines the designation of Charpy impact testers or Charpy impact testing machines. The base components of a Charpy tester are the machine frame, a weighted pendulum rod with hammer, a dial gauge, specimen supports, and a safety .

charpy impact testing procedure

The Charpy impact test is still used throughout sectors to assess material toughness, from construction and manufacturing to engineering and beyond. This test offers practical insights into how materials respond to sudden, dynamic impacts. Even as businesses change, the Charpy impact test is still a valuable and essential tool. How Charpy impact tests are performed. Specimen Preparation: A small, standardized specimen, usually a rectangular bar with a V-shaped notch machined on one side.The notch creates a stress concentration that promotes fracture when impacted. The test setup includes a pendulum hammer, a notched specimen holder, and a digital or analog . An Izod impact testing apparatus — which is essentially identical to a Charpy impact testing machine — is used to determine Izod impact strength. The primary differences between the Izod and Charpy impact tests are the size of the test specimen, how it is restrained, and which side is struck by the pendulum hammer.

Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered.The Charpy impact test is performed to evaluate the resistance of the metal to breakage by flexural shock or impact load according to standard test method ASTM D6110. Fig 1: Charpy Test Apparatus. This test determines the amount of energy absorbed by a material during fracture. This absorbed energy is a measure of a given material’s notch .

measuring thickness using nanospec

For a comprehensive solution to test impact toughness in metals, our Charpy Impact Tester for Metals is designed to meet ASTM E23 standards, ensuring high-quality and reliable results. If your focus is on plastics or polymers, the Charpy Izod Pendulum Impact Tester for Plastics is perfect for assessing the toughness of non-metal materials. ASTM E2248 – 18: Standard Test Method for Impact Testing of Miniaturized Charpy V-notch Specimens.; Ductile to brittle transition in impact testing. Carbon steel and low alloy steel are characterized by the fact that the fracture behavior changes as the temperature drops and the fracture type changes from ductility to brittleness.This page introduces the Charpy impact test principle and methods; as well as evaluation methods, test piece standards, differences from the Izod impact strength test, and methods for measurement of the fracture surface. The 3D Solutions Library operated by KEYENCE introduces examples of shape measurement problems and the latest solutions for various industries, .Charpy impact testing provides a wealth of material data with a single impact strength test, helping determine if your material is suitable for its intended application, ensuring safety and integrity of components and finished products. Supported by our ISO 17025-accredited testing laboratories, Element’s Charpy impact test services deliver .

The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures. Learn more about the .Schematic of a Typical Charpy Impact Testing Machine. In carrying out a test, the specimen is loaded into the anvil with a pair of special tongs that facilitate location of the specimen in the machine. The specimen is supported at each . Best Equipment for Izod and Charpy Impact Testing. An exemplary tool that stands out for its capability to handle these types of tests is the Class J Impact Testing System. Our system showcases a blend of .

Charpy Impact Testing, also known as the Charpy V-notch testing, helps determine a material’s toughness. In our comprehensive materials testing labs our experts perform this test in accordance with multiple standards including .

The Charpy V-notch-CVN impact test also known as the Charpy V- notch test, is a standard test used to measure the impact energy (also referred to as notch toughness) absorbed by a material during fracture. The notch provides a point of stress concentration within the specimen and improves the reproducibility of the results. A Charpy test determines the impact toughness of metal samples by striking them with a swinging mass. The traditional test method requires measuring the difference between the height of the striker before and after impact. An instrumented striker, on the other hand, has force sensors on the striker's edge, allowing scientists to record the .Tensile impact test procedures. The tensile impact strength test was originally developed to overcome the deficiencies of flexural (both Izod and Charpy) impact test. All the test variables that have a high effect on the results, such as notch sensitivity, toss factor and specimen thickness, are eliminated in the tensile impact test.Charpy impact testing (also known as a Charpy V-Notch test) is a valuable method to determine the amount of energy a material absorbs during fracture. The test is performed when a pendulum head is dropped from a specified height and impacts a notched specimen of material.

The Charpy impact specimens of each material are immersed in a bath for 10 minu tes to reach thermal equilibrium at five separate temperatures ranging from 110oF (-79oC) to 212-oF (100oC). The specimens are quickly transferred to the Charpy testing machine, fractured, and the impact energy is measured. After The Charpy impact test can adequately detect this brittle-toughness transition temperature, providing key data on the material’s limits of use. It must be noted, however, that the Charpy test is less useful for comparing the toughness of different metals but is more suited to providing information on the behavior of a single material at .

Impact test. Measures the ability of a material to absorb a sudden application of a load without breaking. The Charpy test is a commonly used impact test. Lateral expansion. The lateral change in dimension of a Charpy impact specimen due to fracture. The dimension measured is the width opposite the v-notch (see Fig. 1-3). Impact testing is required for many critical applications in the construction, machinery and equipment, defense, and energy markets. Charpy testing provides data needed to ensure the quality and reliability of structural steel products. Over 1,000 machines per year are evaluated for conformance with

the standard has been brought in line with IS0 148-1988 ‘Steel - Charpy impact test ( V-notch )‘, issued by the fnternational Organizetion for Standardization (ISO). 4 Printed rt New India Rinti~ Pmr Khwjr, India . Title: IS 1757 (1988): Method for charpy impact test (V .

Drop Weight Impact Testers. Instron Drop Towers are used to develop, fine tune, and validate material models. The new 9400 Series produces reliable, repeatable results whether you are testing materials and components before production to improve product acceptance or testing during production to ensure continuous improvement. More Info

charpy impact testing methods

measuring thickness using sem

measuring thickness with imagej

WEBSunday 18/04/2021. FT. Atlético Bucaramanga. 4 - 1. Águilas Doradas. View events. Sunday 18/04/2021. FT. Deportivo Pereira.

carpy impact testing|charpy impact testing methods